January 24th | 3 min read

Lori Kesten

How to avoid “Islands of Automation”

If you haven’t heard of a Multi Agent Orchestration (MAO) Platform, you’re not alone, it’s new.

Process & Facility Design

“Multi Agent” = many forms of automation equipment, including humans performing work/tasks directed by a system.

“Orchestration” = a platform that integrates multiple systems then uses the shared data to optimizes configured process workflows and adapts to changing demands, capacity constraints, and conditions in real-time.

Automation equipment is not new, and in the past, many organizations that deployed multiple types of automation faced the notorious “islands of automation” issue—where systems operated in isolation, resulting in fragmented and inefficient workflows. Today, as companies increasingly plan to deploy a greater variety of automation solutions, this challenge will intensify, with more isolated systems and wider gaps in operational flow, making seamless coordination more difficult than ever to achieve.

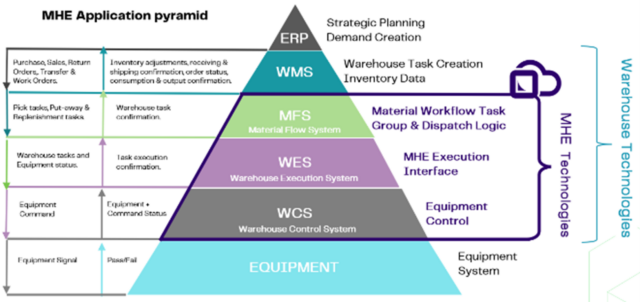

If you are familiar a Warehouse Execution System (WES), at first glance, a MAO platform appears similar, however, upon closer examination, key differences emerge.

In this blog post we’ll begin to break down those distinctions for you.

Five Key Points: WES vs. MAO

1. Scope of Control

- WES: Have been around for decades and were primarily focuses on task execution, it shares data with each equipment vendors WCS to coordinate equipment like conveyors and sorters and “hands- off” to a next step/system in a workflow.

- MAO: Is comparably new and expands beyond task execution by orchestrating multiple autonomous systems, such as AMRs (Autonomous Mobile Robots), goods-to-person systems, and the equipment historically integrated with a WES. A MAO act as a unifying layer that ensures seamless coordination across all systems, including both automated and human-driven processes.

2. Architecture, Adaptability, and Flexibility

- WES: Typically follows predefined static rules and workflows. Adjusting these workflows often requires manual intervention or reconfiguration. A WES most often has been built on older technologies not suitable for a hybrid cloud infrastructure.

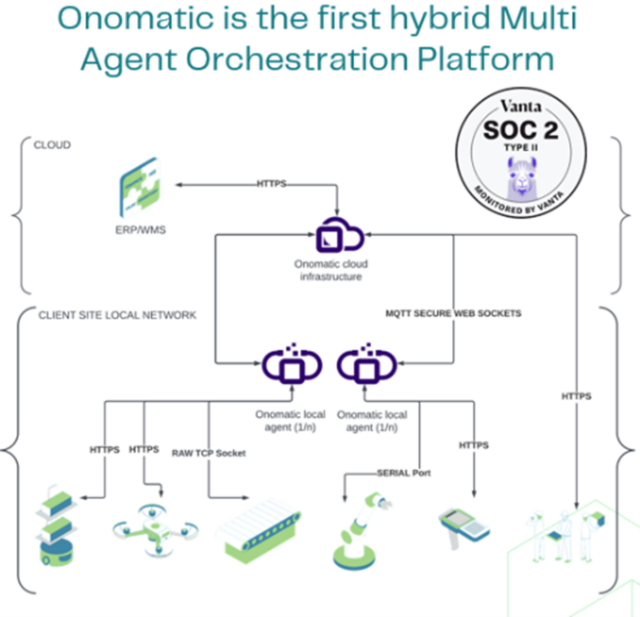

- MAO: Operates using a decentralized, agent-based approach, allowing for real-time adaptability. Each agent (representing a specific system or in a workflow) can autonomously respond to changes, making the overall operation more resilient and flexible. Built from the ground up on new technology, a MAO is able to leverage a cloud and local (edge) infrastructure.

3. Decision-Making Capabilities

- WES: Relies on static logic and rule-based decision-making. While effective in the past, it may struggle with the complex, dynamic environments where priorities shift frequently.

- MAO: Leverages AI-driven agents capable of dynamic decision-making based on real-time data. This allows for more intelligent prioritization and faster response to changing conditions, such as order surges or equipment malfunctions.

4. Scalability

- WES: Designed to handle specific types of equipment, expanding the system often requires significant integration work and can introduce bottlenecks as complexity grows.

- MAO: Built for scalability from the ground up, its decentralized architecture allows new systems, equipment, or workflows to be added without disrupting existing operations, enabling easier expansion as business needs evolve.

5. Orchestration Across Diverse Systems

- WES: Primarily owned by Material Handling Equipment manufacturers, a WES is often included in major hardware purchase. This acquisition model in effect limits future automation choices and pricing negotiation leverage for the end user customer due to competitive & compatibility barriers. Works well within specific environments where it controls or integrates closely with certain types of automation (e.g., conveyors, pick-and-pack stations), however, it may not be designed to orchestrate a wide variety of autonomous robots from different vendors.

- MAO: Primarily owned by Software vendors, it is designed to be automation vendor-agnostic, allowing it to orchestrate diverse equipment systems, whether the agents are the same form from different makers or legacy equipment.

Ideal for operations with a mix of old and new technologies (brownfield sites) as well as new (greenfield sites) because it not only orchestrate all steps in workflow across multiple systems, it can fill in gaps between solutions and support a unified user interface and harmonize data.

In conclusion, a Multi Agent Orchestration platform is the next generation solution in bringing together all forms of automation, real-time data, optimization, execution. By orchestrating tasks, resources, and information within a warehouse, a MAO ensures each investment in new automation will produce the efficiency, accuracy, and productivity they promise.

By understanding these key distinctions, businesses can better assess which solution fits their needs, whether they aim to improve task execution or achieve full orchestration of multi-system environments.

In future posts, we’ll dive deeper into specific use cases, implementation strategies, and real-world results from deploying MAO in a distribution operation.

WES vs MAO – Slang Terms

- A WES (Warehouse Execution System) is a legacy system; a MAO is a next generation system.

- A MHE (Material Handling Equipment) vendor’s core competency is to “bend metal” a Software vendor’s core competency is to “write code”.

- A “proprietary” system means it was not designed to play well with others, an “agnostic” system means intentionally neutral, like Switzerland.

Onomatic is a pioneering software platform redefining warehouse automation with a breakthrough technology category: Multi-Agent Orchestration (MAO). Our vendor-agnostic platform is designed to orchestrate a wide range of automation technologies using configurable workflows, enabling seamless integration and fostering collaboration between human operators and automated systems.

As warehouse automation rapidly advances, the proliferation of autonomous robots and other sophisticated solutions—offered by an expanding range of vendors—has introduced significant operational complexity. This surge in adoption highlights the urgent need for a centralized orchestration layer to streamline processes and maintain efficiency.

A vendor-agnostic MAO platform provides the solution to the “islands of automation” problem by giving businesses the freedom to select and combine automation solutions without being restricted by proprietary limitations or vendor lock-in. Without proper coordination, large-scale automation projects often experience delays, inefficiencies, or outright failure. Onomatic addresses these challenges, enabling organizations to integrate diverse systems smoothly, scale flexibly, and achieve sustainable, future-ready automation outcomes.

Looking to learn more about Multi-Agent Orchestration? Our team will be attending Promat 2025 in Chicago.

Click here to learn more and book an appointment to meet with us there.

Join Onomatic at Promat 2025 | Onomatic

keywords: Wes vs Mao, Warehouse automation, distribution automation, differences between WES and MAO